0577-88630038

current location:home page > Download > Application Case

Source: Runxin Popularity: dateline:[2022-08-30] 【 小 中 大 】

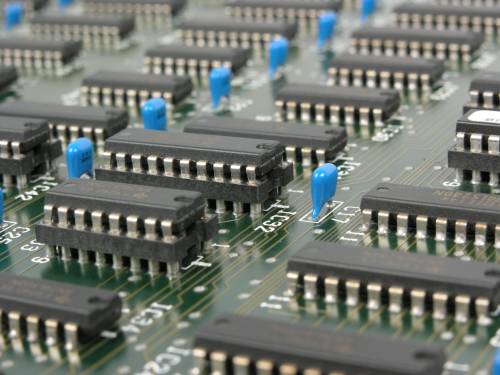

In 1958, TI showed the first integrated circuit board, and the world entered the integrated circuit era. Over the past 60 years, integrated circuit have developed rapidly and have been widely used in industrial, agriculture, aerospace, national defense, military science and so on, and even into every family.

Silicon wafer is an important material for making integrated circuit, it can be made into various semiconductor by means of photoetching, ion implantation and so on. The rapid development of the semiconductor industry has driven the growth of the demand for silicon wafer and put forward higher requirements for quality of silicon wafer, especially for surface quality of silicon polished wafer.

Integrated Circuit

In the production of semiconductor device, the silicon wafer must be strictly cleaned, to clean the pollution impurities on the surface, prevent the failure of device caused by micro pollution. In the production process of silicon wafer cleaning equipment, particles and metal pollution impurities will be generated on the surface, which will seriously affect the quality and yield of device, in order to remove this pollutant, used ultrasonic, acid-base solution and ultrapure water to clean the silicon wafer, the technological process: ultrasonic cleaning - alkali cleaning - ultrasonic cleaning – rinsing – acid cleaning – rinsing – ultrasonic cleaning – drying.

Ultrasonic Silicon Wafer Cleaning Equipment

The wastewater after silicon wafer cleaning contains high hardness silicon wafer residue and acid-base solution, which requires equipment pipeline and valve have good wear resistance, good scour resistance and good corrosion resistance.

Runjing Ceramic Hard Sealing Ball Valve is Applied to Silicon Wafer Cleaning Equipment of a Company in Tianjin

Runjing Ceramic Hard Sealing Ball Valve is Applied to Silicon Wafer Cleaning Equipment of a Company in Zhangjiagang