0577-88630038

current location:home page > Download > Application Case

Source: Runxin Popularity: dateline:[2022-03-04] 【 小 中 大 】

In the iron and manganese removal system, when a single multi-functional flow control valve can’t meet the needs of users for different water treatment methods and water capacity, a control system consisting of multiple Runjing electric ceramic hard sealing ball valves and ball valve controllers can be used. It automatically control the process of iron and manganese removal equipment to meet the requirements of actual projects.

Setting multiple Runjing electric hard sealing ball valves in the system at different points, and complete the operations of the equipment in different opening and closing sequences at different times, so as to complete the oxidation, filtration service, regeneration, backwash, fast rinse and other processes for iron and manganese removal in turn, to form a dynamic chain of iron and manganese removal processes to reduce iron and manganese content and purify water.

A thermal heating company in northern China needs to use two 100m³/h hot water boilers for heating. The raw water is groundwater. The average content of iron ions in its water is 29.5mg/L, and the content of manganese ions is 3.5mg/L. In order to prevent the deposition of iron and manganese oxide scale on the heating surface of the boiler, and avoid iron ions contaminating the resin during softening treatment, the iron and manganese removal treatment must be carried out first, and then softened water treatment be carried out.

Home heating pipe

According to the Chinese GB/T 1576 "Water Quality of Industrial Boilers" standard, the iron content in the make-up water of hot water boilers should not exceed 0.3mg/L. The iron content in the raw water is as high as 29.5 mg/L, which seriously exceeds the standard. In order to make the iron removal treatment meet the standard requirements, the iron removal and manganese removal treatment should be carried out after full aeration.

The project equipment adopts JM-3 filter material to remove iron and manganese at the same time. During operation, first adjust the PH value of the influent water to 8.5, and then pass the aeration device (oil-free air compressor) to fully mix the water and air, so that the ferrous iron and manganese are oxidized into ferric iron and tetravalent manganese. The filter with JM-3 filter media removes iron and manganese at the same time. When the amount of water produced in the iron and manganese removal operation reaches the set value, the filter material is regenerated with a 2.5% concentration NaOH solution to restore the processing capacity of the filter material.

During regeneration, 0.8 times the volume of the filter material and 2.5% concentration NaOH solution is injected into the filter material through the regeneration pump, and then returned to the regeneration tank. After this cycle for three hours, turn off the regeneration pump, soak for three hours. The raw water washes out the regeneration liquid in the tank until the PH value of the effluent is less than 8.5, and the precipitated iron and manganese oxides stored in the filter material can be removed, thereby realizing the reuse of the filter material.

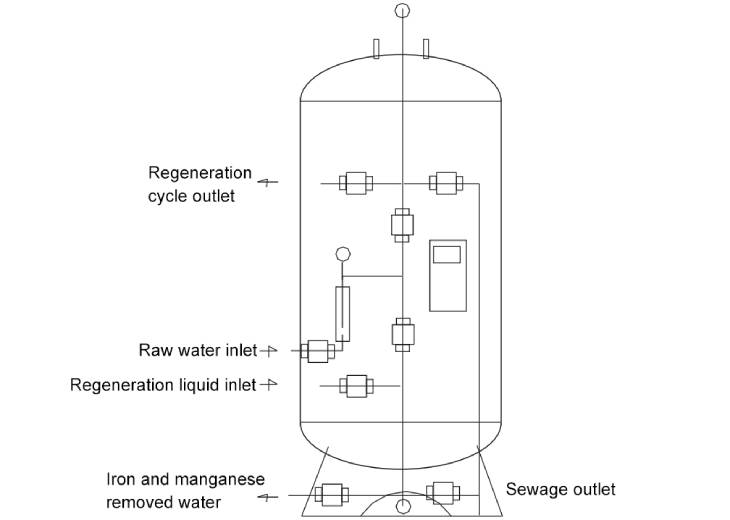

Iron and manganese removal system and equipment

Due to the high iron content in groundwater, the system is designed to filter at a slow flow rate which controlled to be 8m/h; the system is equipped with a set of glass FRP tanks with a diameter of 1.8m and a height of 2.85m and filled with JM-3 filter material. The automatic control system composed of multiple Runjing DN50 ball valves and ball valve controllers is used to remove iron and manganese.

The process flow of the system is as follows: groundwater → frequency conversion pump → PH adjustment device → aeration device (oil-free air compressor) → iron and manganese removal equipment (with regeneration device) → water purification tank → frequency conversion pump → user.

Installation diagram of iron and manganese removal system

After groundwater aeration, the colloidal oxides generated by the oxidation of ferrous and manganese are removed by JM-3 filter material adsorption and chemical reaction. After testing, the iron content of the filtered water is less than 0.1mg/L, and the manganese content is less than 0.05mg/L. The water quality of the water storage tank is clear and transparent, colorless and odorless.

Because the filter material can be regenerated by NaOH in time to restore the effect of iron and manganese removal, unlike manganese sand and other filter materials that need to be replaced regularly, so its operating cost is low, and the JM-3 filter material has a long service life, which can average more than 10 years. The system was commissioned in 2011 and is still functioning normally.